Whether it is in your shop at home, or your regular job is woodworking, there are many hazards to be considered. Proper protective equipment must be utilized to minimize danger. Most woodworking machines now have guards that come as standard equipment. If yours does not, install one. There are fixed, adjustable, and self-adjusting types of guards. Each one has its own advantages and limitations. It is always important to provide a guard or barrier that prevents access to the danger area.

In industries, workers should be trained to understand controls on machines, how to stop equipment in emergencies, and taught safety procedures for special set-ups.

Good housekeeping must be practiced to keep dust from collecting in order to control fire and explosion hazards. Engineered control technology is proper exhaust ventilation and correct use and storage of flammable materials.

Dangers of woodworking include:

- Lacerations

- Amputations

- Severed fingers

- Blindness

- Respiratory problems

- Hearing problems

- Skin disease from exposure to finishing chemicals

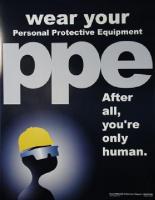

Utilizing personal protective equipment, such as hardhats, gloves, earmuffs, earplugs, safety shields, and goggles will help reduce or eliminate the dangers of woodworking.

OSHA