Today’s guest post is sent to us by Jack Rubinger, www.duralabel.com/. Working around electricity can be very dangerous, so pay attention to these excellent safety tips from Jack:

Look up!

Electrical hazards are overhead. Live wires run dangerously close to cranes, drilling rigs, backhoes, dump trucks and tree trimmers.Electrical hazards are the second leading cause of deaths in the construction industry, killing an average of 143 construction workers each year, according to The Center for Construction Research and Training.

Isn’t it time for a renewed call for visible cues to warn us of electrical hazard dangers from up high, down low and both inside and outside our facilities? New sign and label materials will hold up for years in all kinds of weather conditions – making them ideal for electrical hazards which may occur in facilities and outdoors. A new puncture-proof, water-proof and mildew resistant fabric-like stock is made to survive extreme outdoor and indoor conditions. Proper labeling doesn’t just save time and money, it saves lives. Accidental contact of overhead electrical power lines by mobile equipment is a leading cause of occupational fatalities in the United States, accounting for 20% of on-the-job electrocutions, reported the National Institute for Occupational Safety and Health. Many safety rules and regulations have been established to protect those facing the greatest risks from electrical hazards.

The American National Standards Institute (ANSI) has standards for mobile and locomotive cranes that include operation near overhead power lines and tree care operations that provide safety requirements. Standards address the following issues:

- Consider any overhead wire to be energized unless and until the person owning the line or the utility authorities verify that the line is not energized.

- De-energize power lines before work begins, erect insulated barriers to prevent physical contact with the energized lines, or maintain safe clearance between the energized lines and boomed equipment.

- Notify line owners before work is performed near power lines.

- Post warnings on cranes cautioning the operators to maintain safe clearance between energized power lines and their equipment.

- Review common electrical hazard safety signs and pay attention to important OSHA/ANSI safety codes, standards and regulations.

Make sure to use the appropriate colors, formats and designs as outlined in OSHA §1910.145. Signs used to identify safety issues should be designed in a specified format to comply.

Look down!

Buried or partially exposed power lines are especially hazardous because they carry extremely high voltage. Check work areas for other forms of electrical equipment including street lights and traffic lights – indicators that underground power lines will be present. Look out for sand, plastic strips or specially marked bricks when excavating, which signal the presence of underground power lines. Plans and maps identifying the location of underground cables can date quickly and underground depths can alter road upgrades or developments. The depth of underground cables vary from site to site or even on the same property. Underground cables should never be moved or relocated unless authorized. Below are tasks that expose workers to underground power lines.

- A plumber cutting a water pipe when there could be an electric cable next to the pipe.

- A fencing contractor digging holes where an electric cable could be buried.

- Construction site excavation.

- Jackhammers.

- Well drilling.

- Landscaping.

- Trenching for pipes.

Look inside!

Perform an electrical hazard analysis to review what types of hazards develop in a plant. Look for oil and grease or debris that dissolve or damage insulated cables. Watch out for loose wires that cause electrical shorts and unguarded temporary lights that are exposed to energized parts. Use the guidelines in NFPA 70E and IEEE 1584 to identify and assess electrical shock and risks throughout your facility.

Arc Flash and Solar Panel – Other Electrical Hazards

An arc flash occurs when an electrical short-circuit produces a high-energy, high-temperature explosion. These occurrences are known to propel molten metal and other dangerous debris through the air. Explosions of this nature can damage a person’s eyesight, hearing and cause severe burning or death. For more information about extremely hazardous electrical Arc Flash dangers, visit www.arcflash.me.

Whether the electrical hazard is found indoors, outdoors, far above our heads or buried deep beneath the ground, these hazards need prominent visibility to ensure safe conditions for those who work with or near power lines, tools and construction vehicles. To warn other employees in the facility of the potential hazard, remember to place signs in the area of live repairs being performed. Compliance with sign and label regulations is an important step in the right direction. Protect your workforce by marking electrical hazards clearly.

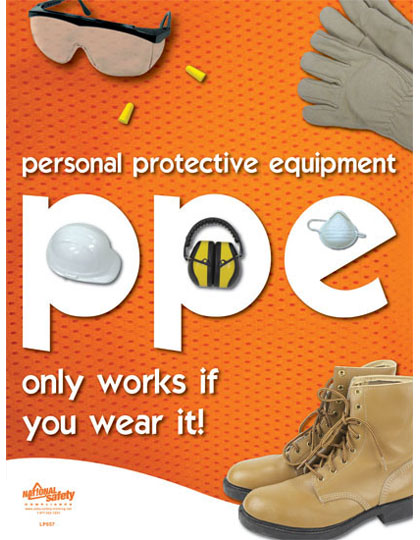

Thank you, Jack, for this article emphasizing the importance of playing it safe around electricity. As he advises, look up, down, and all around to be sure you are not digging or working near electrical hazards! Texas America Safety, www.tasco-safety.com, has special safety glasses that feature a special dielectric hinge design with no metal parts. Also, there are special hardhats that are built for use by utility companies and other industries where head protection with dielectric protection is necessary. Many specialized personal protective products that do not conduct electricity can be found on our site.