If horror movies are to be believed, every encounter with a power tool is just moments away from turning into a terrifying bloodbath. The Texas Chainsaw Massacre, anyone?

But just how dangerous is DIY, really? Are we likely to lose a limb or end up in hospital after trying to carry out a simple home improvement job?

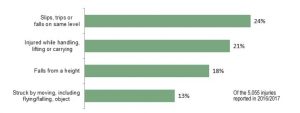

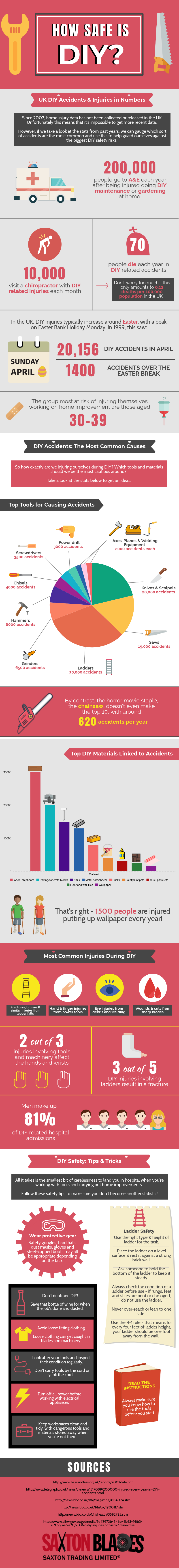

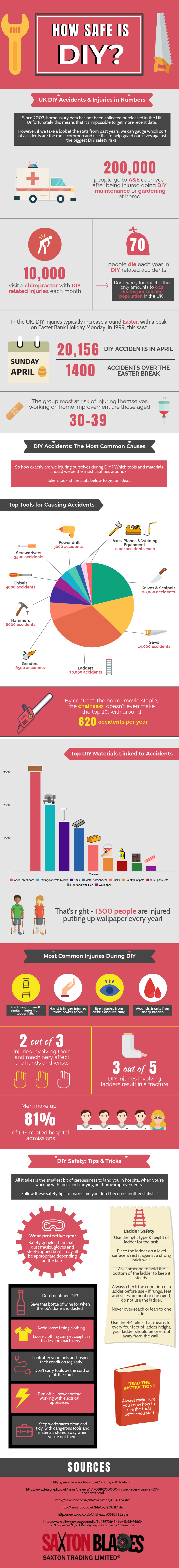

As it turns out, DIY isn’t likely to be fatal. Around 70 people a year die in DIY-related accidents in the UK. This might sound scary, until you consider that nearly 2000 people a year die in car accidents, and that doesn’t stop you getting in your car. Your chances of ending up in a fatal accident trying to replace your toilet seat are very slim!

That said, your chances of being hospitalized in a DIY accident aren’t quite so tiny. Approximately 200,000 people every year are sent to hospital with DIY injuries, with the most common being the result of falls from ladders, and cuts and lacerations from knifes and other sharp blades.

However, you shouldn’t let this put you off. Most accidents are preventable and if you get clued up on proper DIY safety precautions it should all be plain sailing. DIY is empowering and creative, and definitely worth giving a go!

We’ve created this infographic to give you the full lowdown on DIY safety. We’ve perused the available data and compiled all the statistics you’ll need to answer your burning questions:

- How many DIY accidents are there in the UK every year?

- Which tools and materials cause the highest number of DIY injuries?

- What are the most common injuries during DIY?

We’ll also share our top tips for DIY safety and preventing injury!

If you’re looking for more guidance on DIY safety, take a look at these top tips (with a focus on hand and power tools):

- Always wear appropriate protective clothing. Depending on the task, this could mean safety goggles, hard hats, dust masks, gloves, earplugs and even steel-capped boots.

- Avoid loose-fitting clothing, which can get caught in blades and machinery.

- Look after your tools and inspect their condition regularly.

- Never carry power tools by the cord or yank the cord out of the wall.

- Turn off all power before carrying out any electrical jobs.

- Store tools safely away when they’re not in use.

- Always unplug power tools when they’re not in use, or when you want to switch accessories such as blades.

- Keep tools sharp, clean and well-maintained.

- Make sure you’re working in a place where you have good footing and won’t trip over. If possible, try to stay on solid ground when using power tools.

- Keep workspaces clean and tidy to reduce tripping hazards.

- It sounds obvious, but make sure you read the instructions before you use power tools!

- Take care with on/off switches when using power tools, particularly making sure you don’t accidentally turn it on when you don’t mean to.

- Use clamps to secure your work pieces.

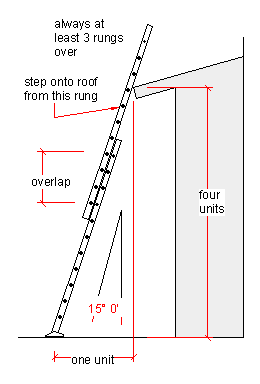

Ladder Safety

Ladder Safety

Be extra cautious when using ladders. Falls from ladders are the single biggest cause of injury when undertaking DIY work, with approximately 30,000 accidents per year that require hospital treatment. Take heed of these safety tips:

- Use the right type and height of ladder for the task.

- Place the ladder on a level, secure surface and make sure it’s resting against a solid wall.

- Always check the condition of a ladder before use. If rungs, feet and stiles are bent , damaged, or missing, do not use the ladder.

- Never over-reach when using a ladder or lean to one side as you could lose your balance and fall.

- Use the 4:1 rule. That means for every four feet of ladder height, your ladder should be one foot away from the wall.

- Don’t leave tools at the top of ladders – they could fall off and injure someone below.

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.