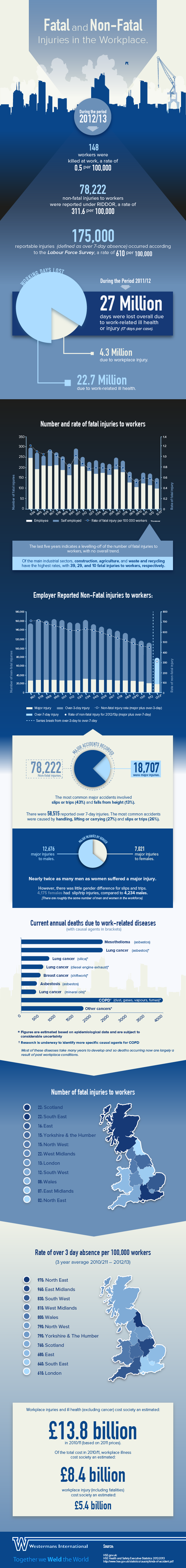

You probably already know that health and safety legislation is a favorite punching bag for a certain type of newspaper columnist, but what you might not be aware of is that there are hundreds of thousands of accidents – many of them serious – in workplaces every year. That’s why it’s so important to take the proper precautions at work.

Of course, even the best prepared among us can still fall victim to accidents at work – but to be forewarned is to be forearmed, as the saying goes. Here, in no particular order, are ten of the most common accidents and injuries in the workplace.

1. Fights at work: These aren’t quite as rare as we might like to think. Simmering workplace tensions can bubble under for months or even years before spilling over into physical confrontation, or alternatively one workmate can take another’s opinion on last weekend’s football the wrong way. Fights in the workplace can, unsurprisingly, result in nasty injuries. Effective procedures for dealing with employee grievances can help reduce the risk of them coming to blows, though.

2. Walking into objects: It’s probably safe to say we’ve all done this at some point. Maybe you’re chatting absent-mindedly or maybe you’re feeling a little under the weather, when you suddenly find yourself on the sharp end of a door, table, wall or cabinet. Needless to say, these injuries can sting a bit. Luckily, many such accidents can be avoided by reminding employees to be vigilant and putting unnecessary hazards out of the way where people won’t walk into them.

3. Slips, trips and falls: Whatever your particular work setting is – whether you work in a shop, a factory or an office – you’re likely to encounter slippery surfaces at some point, so it’s not a totally remote possibility that you might come a cropper on one. Another big risk for many is falling while working at height; falls from ladders are most common, but falls from scaffolding and other platforms can also be dangerous.

4. 2. Muscle strains: Strained muscles are another commonplace work-related injury, as anyone who regularly lifts heavy items at work will probably know already. Back and neck strains, in particular, are all too frequently sustained while working. These injuries can be avoided easily – some basic training on proper lifting techniques can make a big difference.

3. Exposure to loud noise: You might think that industrial deafness is a thing of the past and went out with all those old heavy industries, but that’s not the case – not least because many industrial workers continue to be exposed to loud noises while at work. Industrial deafness can also result in major compensation payouts further along the line, so it’s very much in employers’ interest to nip this particular problem in the bud. Safety measures such as ear protection can do much to prevent it.

5. Being hit by falling objects: Plenty of workers find themselves on the receiving end of falling objects – and what’s more, this isn’t just a problem in warehouse-type environments. Objects which fall from shelves or out of cupboards can cause some nasty injuries, particularly if the individual who ends up feeling the full force doesn’t see it coming. Providing adequate storage cages and reminding employees of how to store items safely can go a long way to reducing this risk.

6. Crashes and collisions: Accidents resulting in crash or impact injuries are also quite frequent at work. Whether they involve cars, lorries or even smaller vehicles such as forklift trucks, they can have seriously nasty consequences. It’s therefore up to employers to ensure that seatbelts and other safety precautions are both in place and in use where appropriate.

7. Repetitive strain injury: RSI is another problem that’s become increasingly commonplace at work over the years, though even now some employers don’t seem to take it entirely seriously. It’s not just a problem for those of us who regularly use keyboards in our work, either – in fact, it can result from any repetitive motion of the joints. The cumulative impact of RSI can be severe in some cases, so it makes sense to take precautions. Employers can help prevent RSI by encouraging and reminding workers to take appropriate breaks. Likewise, ergonomic equipment, like hand trucks can help to alleviate the strain.

8. Cuts and lacerations: All sorts of office implements can end up leaving their user nursing a painful cut. From power saws to paper trimmers, it’s easy to do yourself a mischief at work. The most common causes of these lacerations include poor training, inadequate safety procedures and failing to wear the proper protection. Bosses can help prevent such accidents by providing adequate safety equipment and putting the right procedures (including training) in place.

9. Inhaling toxic fumes: While most of us don’t work with hazardous chemicals, those of us who do may be at risk of skin or eye reactions as well as potentially more serious injuries when exposed to them without protection. Protective equipment such as safety goggles is indispensable in these situations, so employers must be sure to provide workers with the gear they need to avoid dangerous exposure.

10. Exposure to loud noise: You might think that industrial deafness is a thing of the past and went out with all those old heavy industries, but that’s not the case – not least because many industrial workers continue to be exposed to loud noises while at work. Industrial deafness can also result in major compensation payouts further along the line, so it’s very much in employers’ interest to nip this particular problem in the bud. Safety measures such as ear protection can do much to prevent it.

Although there’s no shortage of ways people can injure themselves at work, as we’ve already noted there are various things employers can do to prevent their employees from coming to any avoidable harm. Good training, clear signage and access to the necessary safety equipment can all be a big help. Regular risk assessments are also a very good idea. You can’t always legislate for sheer absent-mindedness, but you can at least avoid a lot of unnecessary mishaps.

If you would like to read this and news about workplace safety visit Slingsby website.