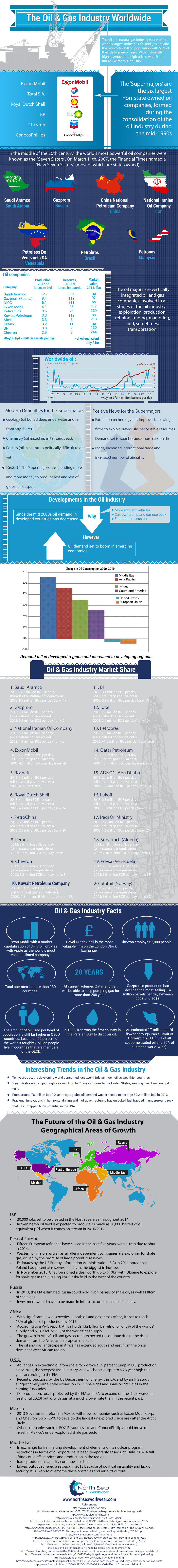

The Washington State area devastated by a mudslide Saturday, March 22nd, has seen much clear-cut logging. Native American tribes and environmentalists have long warned that clear-cut logging could raise the risk of landslides. Although the mountain ranges of the Pacific Northwest may appear solid and stolid, they are a geologically active part of the physical environment, including regular earthquakes, landslides, and the occasional volcano. Sometimes, human activities – including the clear-cut logging that patch-marks much of the region – have an important impact on forests, soils, and water patterns.

The massive mudslide that hit Saturday, March 22, about 55 miles northeast of Seattle was part of that picture, all but wiping out the community of Oso across the North Fork of the Stillaguamish River. As rescue and recovery efforts continued Friday morning, officials reported that the number of confirmed dead remains at 17 with another nine bodies located but not yet recovered. Ninety more individuals are still unaccounted for – large numbers in a small community of around 180 people.

The demand for lumber, plywood, paper, and other wood products is part of an industry that once dominated Washington State and Oregon. Logging’s impact has been a concern for a number of years. Large, older trees take up more water than younger stands, which can take decades to mature and may be cut down before they reach full maturity. The Tulalip Tribes were so concerned with landslides hitting the Stillaguamish River and its prime salmon habitat that they blocked a proposed timber sale above an earlier slide in 1988.”There were some very large clear-cuts planned for that area, which made us very concerned,” Kurt Nelson, a hydrologist with the tribes, told KUOW, the NPR affiliate at the University of Washington in Seattle. “That reach of the North Fork has multiple, ancient, deep-seated landslides,” Mr. Nelson said. “There’s a lot of unstable terrain in that area.” Landslides have followed logging in that area at least four times, KUOW reported.

“This had been known at least since the ’50s as one of the more problematic areas on the Stillaguamish for perennial landslides,” Mr. Kennard, (Geomorphologist Paul Kennard, who worked for the Tulalip Tribes in the 1980s and now works for the National Park Service at Mt. Rainier) reported. Although state logging regulations have been tightened in recent years, The Seattle Times reports that a clear-cut nine years ago “appears to have strayed into a restricted area that could feed groundwater into the landslide zone that collapsed Saturday.”

Heavy rains and winds are hampering rescue efforts, by both professional rescue teams and volunteers. The careful use of heavy equipment, helicopters, and other means of rescue continue. Personnel are wading through debris, muck, trees, ice, and foul water.

Meanwhile, the request by Washington Gov. Jay Inslee (D) for more federal assistance to help with recovery efforts in the Oso area has been approved. The money will be used to help local and state government agencies recover a portion of the estimated $4.5 million expected to be spent on emergency response, protective measures, and debris removal. Safety precautions should be used by all; pros and volunteers. Wearing respiratory protection, gloves, goggles, hardhats, and protective clothing is important for the safety of those exposed to all types of hazards.

At his briefing Friday, Snohomish County Fire District Chief Travis Hots asked corporations and businesses in the region to donate money to help those affected. “Some of these people have lost their homes, some have lost their cars, some have lost their entire family,” he said. “Funerals will have to be paid for. Please dig deep.” Chief Hots is the spokesman for search and recovery efforts.

Source: Christian Science Monitor, Associated Press