First Aid in the Workplace: Team Bonding and Good Sense

Accidents will happen, and it’s a fact that most accidents happen at home or in the workplace. Even minor mishaps can result in injury – tripping on a loose carpet, for example, can lead to a fall and bruising or perhaps a fracture – and it’s not just accidents that require first aid. Some people suffer from conditions that mean they can fall ill, in a variety of ways, without warning, so it pays to be aware of this. At work, it also helps if you know where your first aid equipment is – we’ll come to this in more detail later – so it can be accessed more quickly and easily.

What can you do, as an employer or an employee, to make sure that there are sufficient personnel with first aid experience and knowledge to provide the assistance needed in the case of accidents at work? That’s what we’re going to look at in this short article, where we will also explain how it can be used to encourage team bonding too.

Basic First Aid

So, where do we start when it comes to first aid in the workplace? To begin with, let’s talk about the equipment you should always have close to hand, in the office, factory, shop or wherever it is that you work.

A basic first aid kit should contain the following: plasters, of various sizes; gauze dressings, also in different sizes; eye dressing patches; a variety of bandages; disposable gloves; scissors and tweezers; antiseptic cream and painkillers, plus a thermometer, tape for the bandages, and an eye bath. This is by no means a comprehensive list, as it is simply the basics. You may have certain requirements that apply specifically to your place of work, in which case your first aid kit will differ from some.

Now, that first aid kit should be neatly packaged in a secure box, and be readily available. There should be signage pointing out where to find the kit, and there needs to be responsible persons who are trained in its use, and who are tasked with the act of first aid where necessary. This brings us neatly to the subject of first aid training.

Who Should be Trained?

Every employer has a legal requirement to ensure that the workplace is a safe place in which to work. The regulations covering health and safety at work can be quite daunting, so it is advisable that you put your chosen employees through courses on this, and also send them on any first aid courses that may be relevant to your workplace environment.

The personnel you choose for this training should be trustworthy, reliable and sensible, and it helps if they have some prior knowledge of health and safety at work, and in first aid, although it is not essential. There are many first aid courses that you can send your team on, and some the take place at your premises. They vary in content, but to begin with, a course in basic first aid is perhaps recommended for anyone who has not been through one before. Many employers make this a condition of employment, and with good reason.

A basic first aid course will teach the attendants the simple facts they need to know, and will generally last half a day or a little longer. The attendants will learn about how to act when dealing with an emergency, dealing with heavy bleeding, what to do if someone is unresponsive or not breathing, and handling seizures. They will also be taught what they need to know in the case of someone breaking a bone, how to deal with head injuries, and more. This may sound daunting but it is all useful not just at work, but in everyday life, too.

It’s also worth remembering that first aid courses can be taken in a groups, and this has the benefit of encouraging team bonding. A workforce that learns essential skills together will get to know each other – very helpful if you have new employees who are still fresh to the environment – and most organizations offering first aid training make sure there is a fun element involved in what is a very serious subject, so your team will enjoy the course as well as learning from it.

Learning ABC

Among the primary teachings of a first aid course will be the focus on ABC; this easy to remember mnemonic is designed to remind those in attendance – primarily amateurs such as your working team – about the most important aspects of treating patients in a range of situations.

ABC stands for Airways, Breathing and Circulation. Put simply, these are the three main points to focus on if you find someone is suffering a trauma, has suffered an injury, or you come across someone who is unresponsive. The course will go into more detail, but in brief it is essential that the patient’s airways are kept clear, that they are able to breathe efficiently, and that they have adequate circulation. Attendees of first aid courses will be taught what to do in different circumstances in order to remedy a situation in which any of the above are compromised, to the best of their ability.

No first aid course can teach your team everything they need to know, but what it will do is give them a basic grounding – and more depending on the type of course you choose – in how to handle first aid in the workplace. It is also essential that you book regular refresher courses as skills that are learned but never used can be forgotten. Furthermore, you may have a new intake of employees who need to learn the basics, or one or more of your main first-aiders may move on to a new position.

Check out the various first aid courses available from a range of service providers now and get your team together for an enjoyable and informative, not to mention potentially life-saving, experience that will also help them get together as a team.

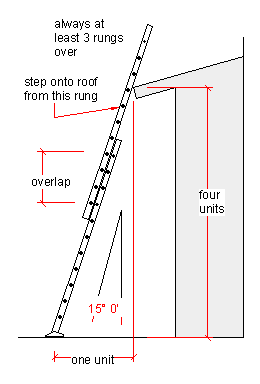

Ladder Safety

Ladder Safety

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.