Today’s Guest Blog is from Joseph Morris at http://www.buy-pepper-spray-today.com. Here are his thoughts on how we can stay safe at the workplace.

Most of us take our jobs for granted. We wake up, go to work, get paid and go home. The thought of an accident or injury is not one that crosses most people’s minds. However, almost all jobs involve some sort of risk – be it large or small – and the awareness of these hazards, and the proper use of safety equipment, is critical to mitigating the incidence of injury on the job.

One of the most important aspects of work safety is training and awareness. New employees, especially those in industries which involve heavy machinery, heavy lifting, chemicals, noise, repetitive movement and heights, need to be trained properly. It is critical that they understand how the equipment that they operate works and what the dangers in their work environment are.

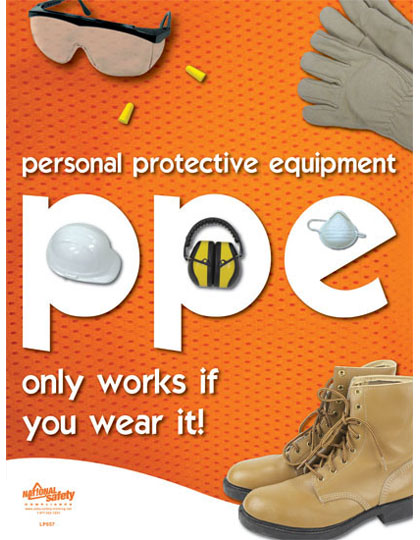

However, training and awareness are not enough. Any industry and its workers would benefit from using the correct occupational safety products. These products can help to protect workers from physical injury, improving productivity and employee confidence, while decreasing employer liability. Let’s discuss some of the most important occupational safety products.

Hearing Protection

The ears are designed to withstand sound pressure levels up to a certain point. After that point, however, hearing damage can occur. The damage may take place over a long period of time, or may have a rapid onset after sudden exposure to loud noise. Ears can be protected with ear muffs or earplugs.

Safety Earmuffs fit over the whole ear – they resemble large headphones. Some ear muffs are adjustable; they can fit on any size of head. In certain industries, muffs which are made of dielectric materials – meaning that they are poor conductors of electricity – are important; they should not attract live currents to the workers head. Some ear muffs offer special acoustic filters which provide an even attenuation of external noise, allowing the worker to hear everything around them at a reduced level, instead of muffling the sound, while protecting their hearing. Ear muffs should be made of resilient material, be lightweight and allow the worker’s ears to breathe.

Earplugs are much smaller than muffs. They fit directly in the ear, and are usually made of a pliable foam or silicone material. The advantages of plugs are that they are lightweight, easy to transport, inexpensive, discrete and easily replaced. Some workers may find them more comfortable than ear muffs. However, some earplugs do not offer sufficient attenuation of outside noise. It is important that the attenuation capabilities be compared with those of ear muffs. If the former cannot provide adequate hearing protection, then the latter must be chosen.

Head Protection

The skull protects the brain, and the head rests upon the neck. Injury to either one can have a serious impact on a person’s functioning and quality of life. Protecting the head on jobs where heavy objects in motion, and the risk of falling objects, are regular occurrences, is critically important. The “tried and true” method of protecting the head is the helmet.

Helmets, most often referred to as ANSI hard hats, are made of hard, durable plastic, often high density polyethylene. Many hardhats include adjustable chin straps to ensure a snug fit. Inside, a suspension system evenly distributes the helmet’s weight over the head More recently, small sizes designed for women, children and men with smaller skulls have been made available, improving both worker compliance and confidence in the appearance of the hard hat. Hard hats should be made of a dielectric material, be able to withstand whichever impacts might take place within a given industry, and be resistant to chemicals which may be used on-site. Some hard hats include ventilation and attachment points for flashlights, radios and other tools.

Work Gloves

Virtually every activity we do, both on and off the job, involves our hands. Protecting the hands at work, from impact injuries, cuts, abrasions, caustic chemicals and repetitive stress, should be a priority. industrial work gloves help to keep the hands safe. Such gloves may range from the simple, rough leather style to more complex gloves, with elasticized cuffs, palm and finger grips, vent holes, knuckle reinforcements and flexible fabric.

The characteristics found in the more complex gloves, such as the ones mentioned above, are an ideal choice for most work environments. They allow the worker to retain dexterity while protecting the hands from most injuries. Jobs which involve dangerous machinery or heavy items may dictate that thicker gloves be used, sacrificing dexterity for the sake of protection.

Ear muffs, earplugs and work gloves are not the only types of occupational safety products. Many others, including ergonomic office products, first aid products, protective clothing, respirators for environments with poor air quality, safety glasses, safety boots and shoes and lighting and communications systems, should be utilized when and where necessary. Remember, worker safety starts with training and awareness, and is completed by using the correct safety products.

Thank you, Joseph, for this great information regarding the important safety aspects of personal protective equipment and proper training in its use.