By Jack Rubinger www.DuraLabel.com

403-469-3024 – jarubinger@graphicproducts.com

Mine Safety & Health – New DVD from Graphic Products

Portland, OR – Graphic Products, the world’s leading industrial label printer and supplier, has released “Mine Safety & Health”— a mining safety DVD created to generate increased awareness about the dangers of mining and to offer safety sign and label solutions. Mining disasters are dramatic and extremely dangerous. Know what to expect and how to lead workers to safety with this free DVD, which is available to those who fill out a form located at http://duralabel.com/free-gifts/free-msha-mining-dvd.php.

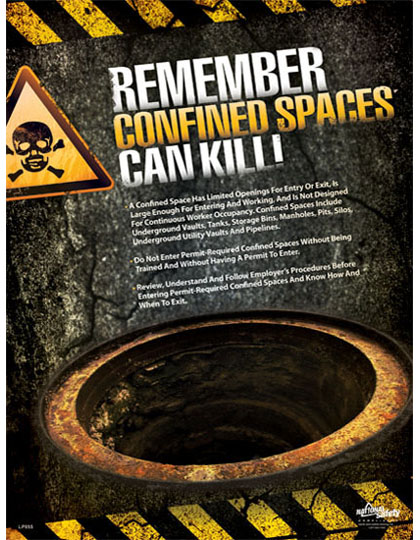

Fires, cave-ins, explosions and other disasters hit miners and their families hard and safety signs and labels must perform 24/7/365 under some of the harshest conditions imaginable – deep underground, covered by soot and dust and in the dark and frigid cold.

Clocking in at more than one hour, this value-packed DVD, viewable in both Spanish and English, educates viewers about chemical hazards, the dangers of dust and introduces the DuraLabel Toro, the first 4-inch, battery-powered, fully network-independent printer that can go anywhere — making it ideal for miners.

Compared to traditional vinyl cutters, which are slow and cumbersome, DuraLabel printers produce a wide range of labels in just minutes.

“Mine equipment operators, mill operators and maintenance personnel face dangers every day, but traditional safety sign ordering methods are costly and too slow to make an immediate impact on safety,” explained Steve Stevenson, Chief Marketing Officer, Graphic Products, Inc. “Many Environmental Health & Safety (EHS) managers still dig through thick catalogs in search of just the right sign with the correct dimensions, colors and MSHA compliant language. Requisitions slow the process further. Ordering custom signs from sign shops is expensive and slow — especially for delivery to remote locations. Ordering signs from catalogs hinders getting signs up quickly.”

The good news? Thermal transfer printers from Graphic Products, Inc. may be ordered directly and delivered overnight to remote sites. Almost immediately, users can create all the signs and labels needed and they’ll perform anywhere in and around the mine. Thermal transfer printers use heat to literally “bake” on graphics and text to vinyl and other supplies which have been tested to perform under the most demanding conditions.

Signs and labels impact every inch of every mine. While no two mines are alike, most will benefit from traffic signs, facility signs, no smoking/cell phone signs, mine permit boundary signs and identification tags for exploration as well as pipe markers, valve tags and high voltage and Arc Flash NFPA70E signs.

Graphic Products, Inc. manufactures mobile and wide-format labeling systems used by mining operations, manufacturers, international shipping lines, distribution centers, and oil refineries worldwide. Customers include Amazon.com, Boeing, Intel and Toyota.

To underscore its commitment to visual communications, Graphic Products provides a growing selection of free published articles, best practice guides, handbooks, webinars, blogs, and informational videos.

Graphic Products offers more than 50 unique labeling supplies for virtually any industrial demand, as well as advanced labeling systems for any size job. DuraLabel and Graphic Products have solved problems in the industrial safety arena for more than 40 years. For more information, visit www.DuraLabel.com, call 800-788-5572 or email Jack Rubinger at jarubinger@graphicproducts.com.