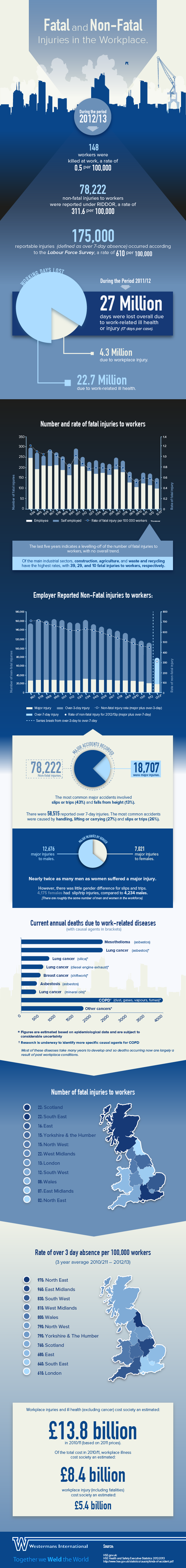

Every year in the United States, workplace electrical incidents result in more than 300 deaths and 3,500 injuries. While electrical hazards are not the leading cause of on-the-job injuries and fatalities, they are disproportionately fatal and costly. For every 13 electrical injuries, a worker dies. Knowing best practices of electrical safety are critical to reducing these staggering statistics because most of these injuries could be prevented.

Electricity and electrical products play a fundamental role in how we conduct business every day. However, if not used or maintained appropriately, they can pose serious risks. Over the last ten years, more than 30,000 workers have been injured in workplace electrical accidents. These injuries not only disrupt the lives of the workers and their families, but also impact the productivity of employers.

An arc flash is a sudden release of electrical energy through the air when a high-voltage gap exists and there is a breakdown between conductors. An arc flash gives off thermal radiation (heat) and bright, intense light that can cause burns and other injuries. Exposure to extreme temperatures burns the skin directly and ignites the clothing that the worker is wearing.

An arc flash can be spontaneous, or can result from inadvertently bridging electrical contacts with a conducting object. Other causes may include dropped tools, the buildup of conductive dust, or corrosion. While great advances are being made to improve equipment design and thereby reduce the number of arc flash incidences, there is still much to be done. Each year, 2,000 workers are admitted to burn centers for treatment of severe arc flash burns.

High-voltage arcs can also produce considerable pressure waves by rapidly heating the air and creating a blast. This pressure burst, or arc blast, can hit a worker with grenade-like force and send metal droplets from melted copper and aluminum electrical components shooting out at speeds up to 700 miles per hour – fast enough for the tiny shrapnel to penetrate ones body.

Here are some important ways to prevent injuries and fatalities when working with electricity:

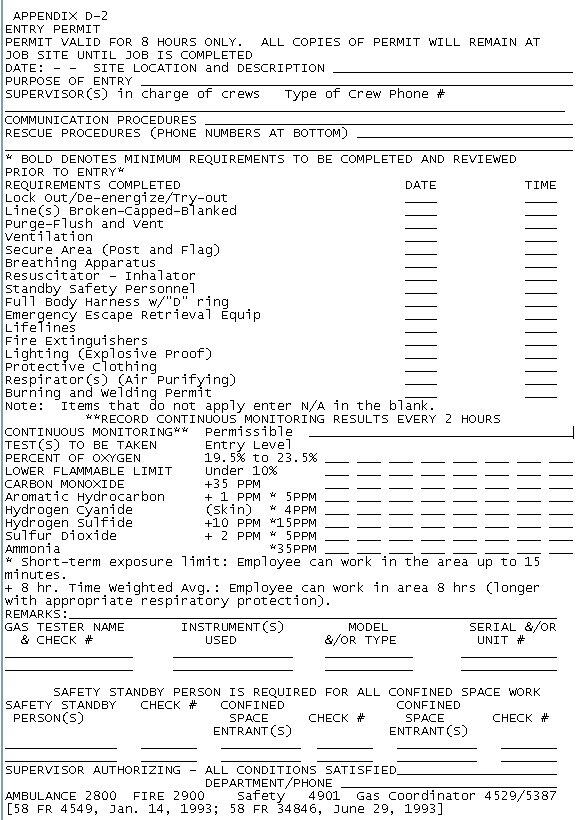

Every year, workers are injured or killed by circuits they thought were safely turned off. Simply shutting off the power is not enough. Hazardous conditions can still exist. You may not get a second chance to learn this important lesson, so always test before you touch!

Most electrically-related fatalities and injuries could easily be avoided. Responsibility for your safety begins with you. Take steps to protect yourself everyday and make safety an integral part of how you do business.

| The number one way to prevent electrical injuries and fatalities is to turn off the equipment being worked on. It may take a little more time and planning, but your life and your health are worth it. Be proactive about de-energizing equipment and taking steps to ensure that your work environment remains safe. Working on energized equipment increases your risk of injury or death. |

| Each day, nearly 3 million professionals participate in work activities where lockout/tagout procedures should be used. Unfortunately, too many workers still put themselves at risk by working energized or neglecting to follow their company’s lockout/tagout procedures. Year after year, failure to comply with the lockout/tagout standard is listed as one of the top OSHA violations. If the standards are followed, an estimated 120 fatalities and 50,000 injuries could be prevented annually. Get in the habit of doing this important step every time! |

Personal Protective Equipment (PPE) will be the major factor in differentiating between an electrical event you walk away from and one that requires months of painful healing. PPE comes in many different forms, including: hard hats, gloves, goggles, safety shoes, flame-resistant clothing, dielectric safety glasses, face shields, fall protection equipment, etc.Be sure to choose the PPE that is right for you and your circumstances. PPE should be:

This month serves as a reminder that we must always be extremely careful when working around electricity. |

| Source: ESFi (Electrical Safety Foundation international) |