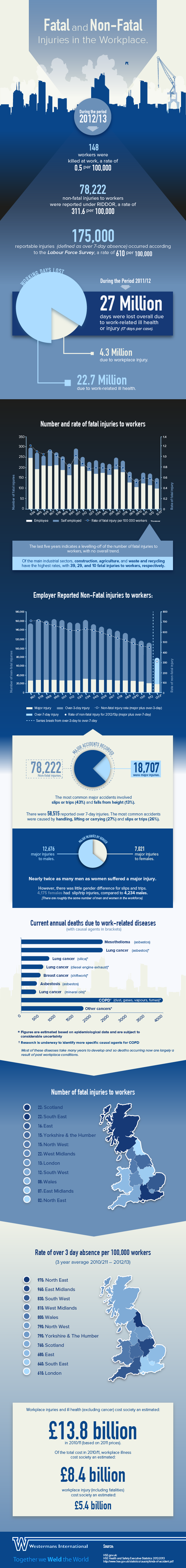

This interesting infographic is from Rebecca Fox, of Westermans International, a UK-based welding company. We appreciate this shared information and can learn what illnesses are prevelant in their respective industries.

Tag Archives: lung cancer

IMPORTANT INFORMATION ABOUT PROPOSED WORKPLACE STANDARD REGARDING SILICA DUST

Our parent company, Texas America Safety Company, recently received this information, and we want to pass it on to our readers, because you can help.

As you may know, about 1.7 million workers in the United States each year are exposed to silica dust and run the risk of developing silicosis, lung cancer and other debilitating diseases. Public health experts estimate that 280 workers die each year from silicosis—and thousands more develop silicosis as a result of workplace exposures.

But a proposed workplace standard on silica dust exposure from the Occupational Safety and Health Administration (OSHA) has been delayed for nearly two years as the Office of Management and Budget reviews the proposed standard.

Your membership and audience can help spur action on controlling this deadly workplace hazard by signing a White House “We the People” petition urging the Obama administration to move forward with the silica dust standard.

Laborers (LIUNA) President Terry O’Sullivan says:

Any further delays in the rule-making process will only add to the death toll. The construction industry urgently needs stronger OSHA standards to prevent overexposure to silica dust. LIUNA and our supporters across the country will keep fighting for progress on this issue until a new safety standard is approved.

The petition requires 25,000 signatures by Feb. 11 to elicit a formal response from the White House. Click here to sign the petition.

The current delay in moving ahead with a silica dust standard is just the latest in what is now a 15-year saga of trying to protect workers, even though the dangers of exposure to silica dust and the crippling and fatal lung disease it causes have been known for decades.

At a Senate hearing last year focusing on the innumerable delays and roadblocks new OSHA safety standards must clear before becoming law—about eight years—Sen. Tom Harkin (D-Iowa), chairman of the Health, Education, Labor and Pensions Committee, blasted corporate opposition to workplace safety laws and anti-worker lawmakers for blocking needed safety measures.

Today, rather than hearing outrage over worker deaths, we hear misinformation campaigns from corporate lobbyists about OSHA supposedly killing jobs. We see legislative proposals that call for blanket prohibitions on new regulations and proposals to add even more red tape to the regulatory process….We must come up with ways for OSHA to do its job without intimidation or interference.

Strategic Communications Department

Tad Kicielinski / Media Outreach Manager

Note: For your information, Blog4Safety wishes to explain more about silica dust to help in your decision regarding the petition:

What is crystalline silica?

Crystalline silica is a basic component of soil, sand, granite, and many other minerals. Quartz is the most common form of crystalline silica. Cristobalite and tridymite are two other forms of crystalline silica. All three forms may become respirable size particles when workers chip, cut, drill, or grind objects that contain crystalline silica.

What are the hazards of crystalline silica?

Silica exposure remains a serious threat to nearly 2 million U.S. workers, including more than 100,000 workers in high risk jobs such as abrasive blasting, foundry work, stonecutting, rock drilling, quarry work and tunneling. Crystalline silica has been classified as a human lung carcinogen. Additionally, breathing crystalline silica dust can cause silicosis, which in severe cases can be disabling, or even fatal.

What can employers/employees do to

protect against exposures to crystalline silica?

- Replace crystalline silica materials with safer substitutes, whenever possible.

- Provide engineering or administrative controls, where feasible, such as local exhaust ventilation, and blasting cabinets. Where necessary to reduce exposures below the PEL, use protective equipment or other protective measures.

- Use all available work practices to control dust exposures, such as water sprays.

- Wear only a N95 NIOSH certified respirator, if respirator protection is required. Do not alter the respirator. Do not wear a tight-fitting respirator with a beard or mustache that prevents a good seal between the respirator and the face.

- Wear only a Type CE abrasive-blast supplied-air respirator for abrasive blasting.

- Wear disposable or washable work clothes and shower if facilities are available. Vacuum the dust from your clothes or change into clean clothing before leaving the work site.

- Participate in training, exposure monitoring, and health screening and surveillance programs to monitor any adverse health effects caused by crystalline silica exposures.

- Be aware of the operations and job tasks creating crystalline silica exposures in your workplace environment and know how to protect yourself.

- Be aware of the health hazards related to exposures to crystalline silica.

- Smoking adds to the lung damage caused by silica exposures.

- Do not eat, drink, smoke, or apply cosmetics in areas where crystalline silica dust is present. Wash your hands and face outside of dusty areas before performing any of these activities.

- Remember: If it’s silica, it’s not just dust.

Source: OSHA

PROTECT YOUR LUNGS THIS WINTER!

With cold weather, there are many more workers moving indoors, so this is a good time for employers to check the air quality of their employees’ work environment. This is also the opportunity for employers to inventory their supply and usage of NIOSH-approved respirators. It is very important to know the hazardous airborne particles that exist in every workplace.

In the United States, there are an estimated 5 million workers who are required to wear respirators in 1.3 million workplaces. More people still die from lung cancer than from any other type of cancer (over 159,000 deaths per year). Smoking is usually found to be the leading cause of lung cancer; however, workers who wear respirators are better protected from harmful airborne hazards. Some of these hazards have also been known to contribute to causing cancer, lung impairment, other diseases or even death.

“Dust Masks” vs. N95 Respirators

Many people often ask what is the difference between a respirator and a dust mask. Even though their appearances are similar, NIOSH-approved N95 respirators are very different from dust masks. Dust masks provide no proven protection against harmful airborne particles. NIOSH recommends the use of N95 (or better) respirators for most environmental hazards.

In testing, respirators that collect at least 95% of the challenge aerosol are given a 95 rating. (99% receive a 99 rating; at least 99.97%, a 100 rating). The filters for respirators are tested by NIOSH at the time of application and periodically afterward to ensure they continue to meet the certification. The certification of N95 will be on the respirator, so you know you are getting the right thing.

It is necessary to perform fit tests to verify there are no defects in the respirators. Please note: Caution:

Respirators must be properly selected and fitted to provide protection to the user. It is the responsibility of the user to make the appropriate choice of respirator based on the contaminant, workplace concentrations, and any other site specific conditions. It is also the responsibility of the user to ensure that the workplace is in compliance with all applicable Federal, State, and Local regulations on worker safety, including, but not limited to, OSHA regulations on respiratory protection (29 CFR 1910.134). Read all Warnings and Use Instructions that accompany the respirators. If you have any Technical questions regarding respiratory protection, call the manufacturer.

Dust Masks are loose-fitting filters that fit over the nose and mouth, capturing dust on the outside when the wearer breathes in air. Respirators have the NIOSH marking on them; therefore, they have met strict criteria and passed independent certification tests established by NIOSH. Their tests ensure the respirator has been designed to meet minimum filtration requirements as well as specific manufacturing quality levels. NIOSH does not test or certify dust masks.

Every worksite has its own level of protection that is required for its specific application. You see respirators used in all types of settings, from the medical industry to industrial applications. The NIOSH website (www.cdc.gov/niosh) maintains a database of all NIOSH-approved respirators for user reference.

Source: Gateway Safety; Texas America Safety Company; OSHA