Sent to us by Karl Young.

Most people would be surprised by what the definition of working at heights is: work at height means working in any place where, if precautions were not taken, a person could fall down and injure themselves.

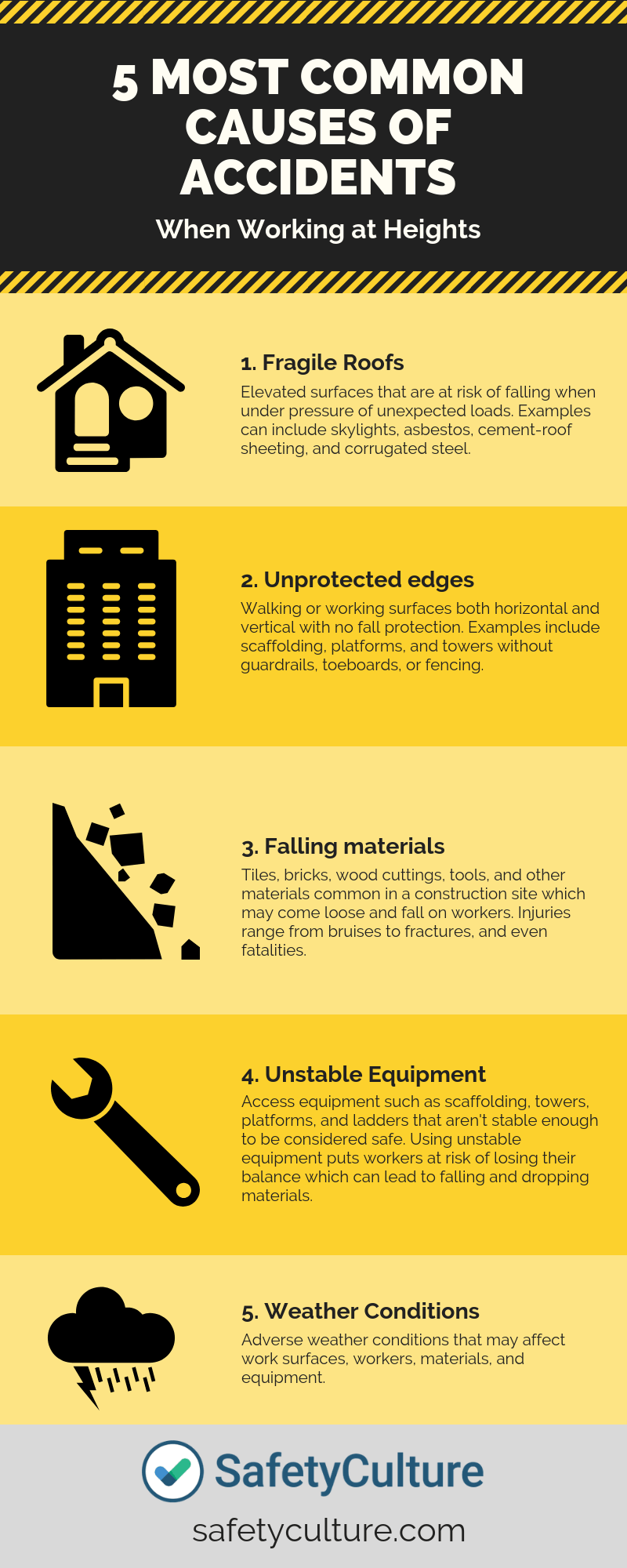

Work at height means working in any place where you work above ground level, could fall from an edge, through an opening or fragile surface; or could fall from ground level into an opening in a floor or hole in the ground. If your job requires you to work with any of the above dangerous then you will be working at height. If on a day to day basis you use working platforms such as scaffolds, tower scaffolds, cherry pickers, scissor lifts and podium steps, work on a roof, piece of plant or equipment; or use ladders or stepladders you and your employer need to be following the working at heights regulations.

Precautions

More often than not you will only be working at heights as a one off, you might be changing a light fitting or climbing a ladder to access storage space. One of the best ways to ensure injury prevention at height is to carry out a risk assessment; this is a simple process which will help you choose the right precautions to take when working at heights.

Small businesses are often the ones that don’t have the right equipment in place to protect their employees from the dangers of working at heights. In most cases injuries and damage can be avoided by investing in long handled tools and other equipment that can sometimes be used to safety carry out a task from ground level. Long handled brushes, roller paint brushes, water fed poles and hatch openers are just a few pieces of equipment that can enable any user to perform a basic task without the need to move above ground level.

Prevention

Employees are most often at risk from falling when working at heights, there are several methods of prevention for falling in the work place that can easily be implemented. You can ensure the fixtures around you are safe and tight, ensure the roof of your premise if accessible is fitted with guard rails. You should always ensure that equipment purchased as a safety precaution is safe to use and has regular checks and maintenance.

Additional measure can be taken at work to reduce the risk of a fall. When using any equipment for work at height you need to ensure that:

- The people using it are trained to use it safely;

- It is regularly inspected and well maintained; and

- The work is supervised to check people are working safely

The consequences of a fall can be minimised if you try and avoid and the prevent a fall before using measures that will only minimise or limit the consequences. A good example of this are safety nets, they can be installed around the edge of a premises roof to minimise the risk of injury if someone falls. Fall arrest equipment will also minimise injury if someone falls, providing the equipment is set up correctly, users know how to look after it and they understand its limitations.

The key to a safe and happy workplace is a knowledgeable employer and employee. The failure to follow and adhere to regulations when working at heights can result in hefty fines and extreme cases employees being injured resulting in a lawsuit. It is best to be knowledgeable and smart when your employee needs to work at heights, visit your local authority’s website for more information on working heights regulations and precautions.

The post was created by Karl Young on behalf of Loxam Access a leading specialist in the rental of Access Platforms, Access Equipment and Cherry Pickers.